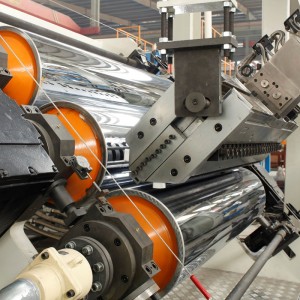

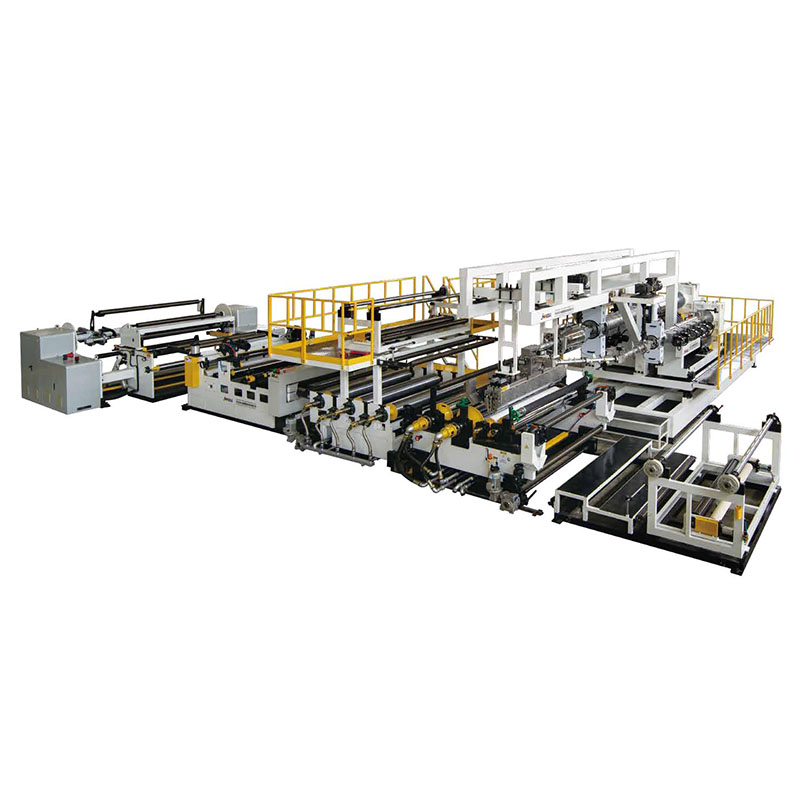

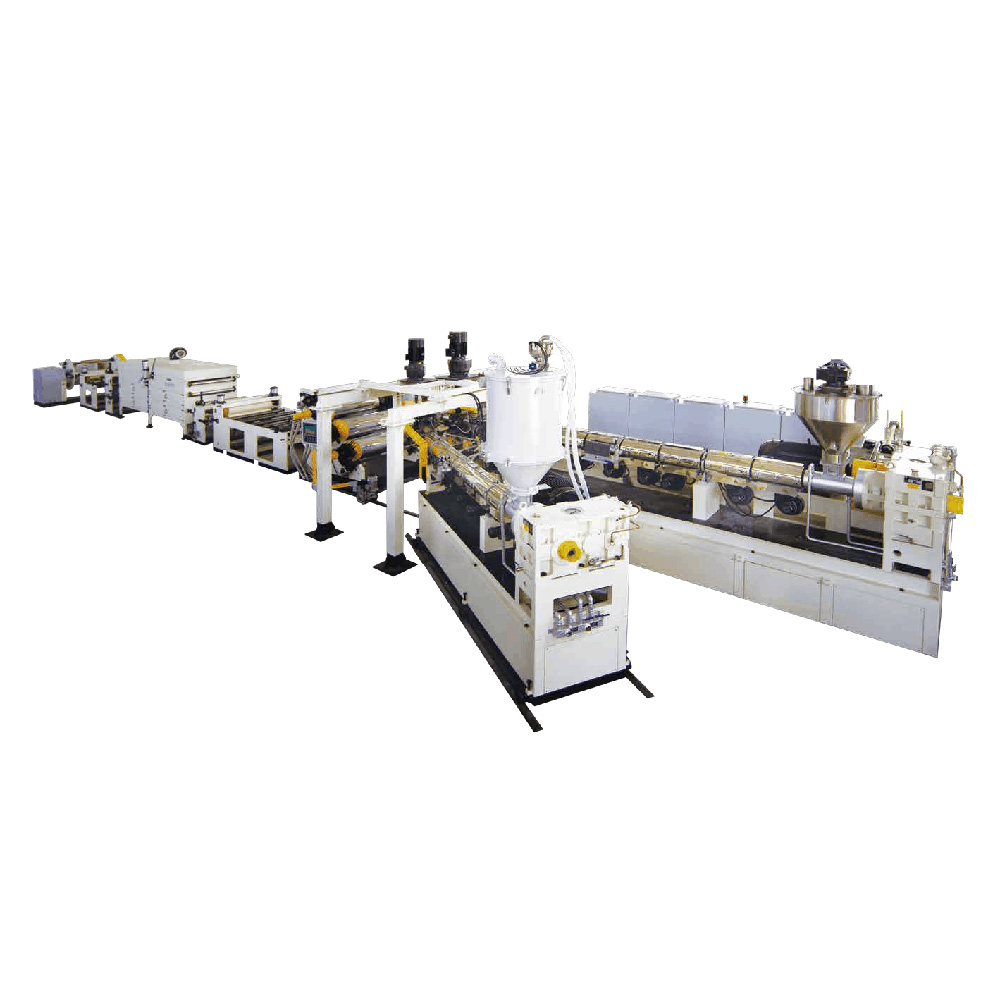

PC/PMMA/GPPS/ABS Plastic Sheet & Plate Extrusion Line

GPPS, general-purpose polystyrene, commonly known as transparent benzene, is a colorless, odorless, tasteless, lustrous, and transparent solid. Transparency 88%-92%, refractive index 1.59-1.60. Excellent electrical properties, excellent radiation resistance.

Polycarbonate, referred to as PC, is colorless and transparent, with excellent heat aging resistance, impact resistance and excellent insulation properties.

Polymethyl methacrylate, referred to as PMMA, also known as acrylic or plexiglass. High transparency, easy to machine, often used as a substitute for glass.

PC/PMMA/GPPS/ABS Plastic Sheet & Plate Extrusion Line Application

Applicable scope of PC endurance board, PC corrugated sheet

Garden, recreation place, decoration and the corridor pavilion; Internal and external ornaments in the commercial building, curtain wall of the modern urban building; transparent container of aviation, the windscreen before the motorcycle, the plane, the train, the steamer, the submarine, army and police’s shield, the telephone booth, advertising signpost, the advertisement of the lamp houses, the expressway and overhead way of the city partition protective screen.

PMMA board (Acrylic board/GPPS board)

Application of product: common PMMA plate is mainly used in the field of advertisement, decoration, art ware, escutcheon, and specimen, etc; the electroplated plate is used for a plastic mirror; a Light panel is used for ultra lightbox, flat panel display lamp of LED, poster stand and advertising decoration, etc. The LCD panel can be used for the display of computers and television. Suzhou Jwell's plate extrusion line is suitable for producing the PMMA or PC diffusion plate.

1. ABS.HIPS/GPPS Refrigerator board

It has wide application in the production of the refrigerator doors and inner gallbladder, drawers, water dispensers, etc.

2. ABS/PMMA Sanitaryware plate

It is widely applied in the field of bath products, such as the bathtub, the shower cabinet, the vapor room, washing bowl, etc.

3. ABS/PC Baggage plate

It is mainly applied in the field of draw-bar boxes, luggage cases, recreation bags, etc.

4. ABS.ABS + PC Car plate

It is mainly used to produce tops of cars and buses, instrument boards, backrests, car doors, window frames, shells of motorcycles, golf vehicles, etc.

PC/PMMA/GPPS/ABS Plastic Sheet & Plate Extrusion Line Main Technical Parameter

| Model | Material | Products Width | Products Thickness | Extruder Specification | Capacity (Max.) |

| JWS130/38- 2200 | PC, PMMA, GPPS, ABS | 2200mm | 1.5-10mm | 130/38; 45/30 | 550Kg/h |

| JWS120/38-1400 | PC, PMMA GPPS ABS | 1400mm | 1.5-10mm | 120/38 | 450Kg/h |

FAQ

● International Commercial Terms(Incoterms): FOB, CFR, CIF, EXW.

● Terms of Payment: LC, T/T.

● Average Lead Time: Peak season lead time: 3-6 months, Off season lead time: 1-3 months.

● Number of Foreign Trading Staff:>50 People.

Yes, We own 5 manufacturing bases and sales center in Shanghai, Suzhou, Changzhou, Zhou Shan, Dongguan China.

Jwell made the first Chinese screw and barrel in 1978 in brand name Jinhailuo. After more than 40 years development.

JWELL is one of the biggest extrusion machine supplier in China with 300design&test engineer, 3000 employees.

Jwell has become the premier supplier of extrusion lines and reliable business partners. Welcome to drop in us.

Our machines taking the European standards and follow the Germany type of business, we cooperation with International famous brands Siemens Schneider Flender Omron ABB WEG Falk Fuji etc. Our company continuously imports over 1000 international first-class high precision processing equipment such as multistage machining centers, CNC lathes and CNC milling machines from Korea, Japan etc. All our processes strictly adhere to CE certification, IS09001 and 2008 quality management system. And we have 12 months quality warranty time. We testing the machine performances before each delivery. Jwell service engineers will always be here for anything you needed.

Usually it takes about 1 – 4 months depends on different machinery upon receipt of order advance payment.

Once clear your requirements and determined extrusion line is ideal for you. We will send technical solutions and Proforma Invoice to you. You can pay via TT bank transfer, LC as you like.

One. We provide both customized extrusion lines and technical solutions. Welcome contact with us for technical innovation or improvements for your future purchasing plan.

We produce more than 2000 advanced extrusion lines every year world wide.

We can send the small spare parts by air express for urgent matter. And the complete production line by sea to save the cost. You can either use your own assigned shipping agent or our cooperative forwarder. The nearest port is China Shanghai, Ningbo port, which is convenient for maritime transportation..

Yes, we support our business partners by pre-after sale service. Jwell has more than 300 technical testing engineers traveling world wide. Any cases would be responded with prompt solutions. We provide training, testing, operation and maintenance service for a life time.

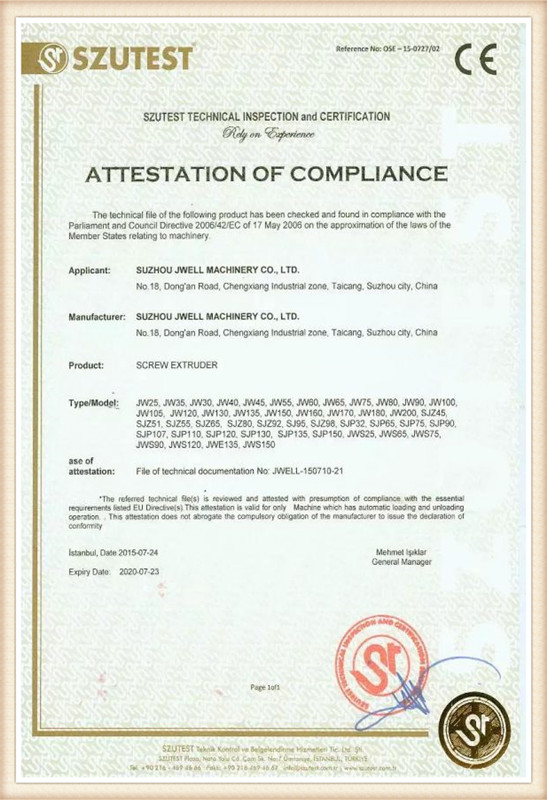

Certificates

Certified By: SGS

Extrusion Down Stream Equipment

2015-07-23 ~ 2020-07-23

Certified By: SGS

Extrusion Down Stream Equipment

2015-07-23 ~ 2020-07-23

Certified By: SGS

Extrusion Down Stream Equipment

2015-07-23 ~ 2020-07-23

Certified By: SGS

Extrusion Down Stream Equipment

2015-07-23 ~ 2020-07-23

Certified By: Other

Design, Development, Manufacture And Sales Of Intellectual Property Rights Management For Plastic Machine

2016-06-14 ~ 2019-06-13

Certified By: Other

Design, Development, Manufacture And Sales Of Plastic Pipe And Sheet Extrusion Production Line

2018-11-20 ~ 2021-11-19

Certified By: Quality Austria Training, Certification and Evaluation Ltd.

Plastic Extrusion Line

2010-01-29 ~